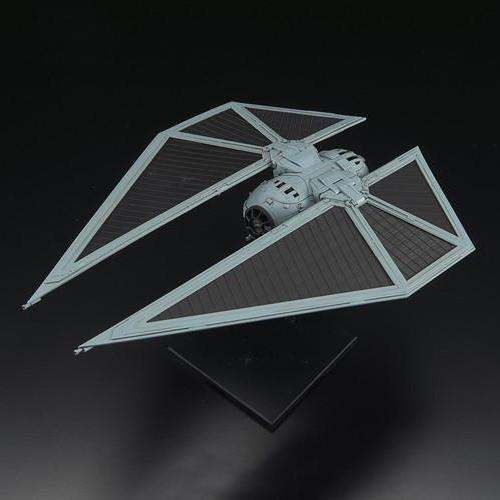

Buy Square Tube Plastic Model Kits for Scale Modelling Now!

By:Admin

At Scale Model Shop, we are proud to offer a wide variety of square tube plastic model kits for our customers. Whether you are an experienced model builder or just starting out, we have something that will fit your needs. Our kits come in a range of sizes and styles, so you can find the perfect fit for your project.

One of the great things about square tube plastic model kits is that they allow for a lot of creativity in the building process. With a few simple tools, you can easily cut and shape the tubes to create any number of designs and shapes. This means that you can truly customize your model and make it your own.

Our kits are designed to be easy to assemble, even for those who are new to scale modelling. We provide step-by-step instructions that are clear and easy to follow, so you can get started right away. And if you ever have any questions or need some extra help, our customer support team is always available to assist you.

Of course, the real beauty of square tube plastic model kits is in the finished product. The tubes provide a clean, modern look that is perfect for a wide range of projects. Whether you are building a model of a building, a vehicle, or something else entirely, the square tubes can add an extra level of detail and interest that other materials simply can't match.

At Scale Model Shop, we are committed to providing our customers with the highest quality products and customer service possible. We work with some of the best manufacturers in the industry to bring you the latest and greatest products on the market. And our team is passionate about scale modelling, so we are always happy to answer any questions you may have or help you find the perfect kit for your project.

Overall, we believe that square tube plastic model kits are an excellent choice for anyone who wants to create a truly unique and customized model. With their flexibility, ease of use, and stunning finished products, these kits are sure to impress even the most seasoned scale modellers. So if you are looking for a new project or just want to try something different, be sure to check out our selection of square tube plastic model kits today!

Company News & Blog

Benefits of Using Capillary Tubes for Isolating Measuring Instrument and Tapping Point

Capillary Tube Material: Understanding the Advantages and DisadvantagesCapillary tubes are small diameter tubes that are used in various industries to measure liquids and gases, and to isolate the measuring instrument from the process tapping point. The tubes are made in a variety of materials, each with its own advantages and disadvantages. In this blog, we will explore the different capillary tube materials, their properties, and their applications.Stainless Steel Capillary TubesStainless steel capillary tubes are the most commonly used capillary tubes in the industry due to their high corrosion resistance and durability. They are made from high-quality stainless steel and are ideal for use in applications that require high precision and accuracy, such as in chemical plants, laboratories, and pharmaceutical industries. Stainless steel capillary tubes are also resistant to high pressure and temperatures, making them a durable option for measuring in harsh environments.However, despite their many advantages, stainless steel capillary tubes can be difficult to bend and shape, making them unsuitable for certain applications. They are also relatively expensive compared to other materials.Copper Capillary TubesCopper capillary tubes are commonly used in refrigeration and air conditioning systems due to their excellent thermal conductivity and malleability. Copper is also a relatively cheap material, making it a cost-effective option for many applications. Copper capillary tubes are easy to bend and shape, making them ideal for use in confined spaces.However, copper is prone to corrosion and can react with certain chemicals, limiting their use in certain environments. They are also less durable than stainless steel, making them less suitable for applications that require high pressure or temperature.Plastic Capillary TubesPlastic capillary tubes are made from a variety of polymers such as polyethylene, polypropylene, and nylon, and are used in various applications such as food manufacturing, medical devices, and electrical equipment. Plastic capillary tubes are lightweight and easy to shape, making them ideal for use in applications that require flexibility and maneuverability.However, plastic capillary tubes are generally less durable than metal capillary tubes and can be prone to cracking and warping under high pressure or temperatures. They are also not suitable for use in certain chemical environments where the plastic may react with the material being measured.Glass Capillary TubesGlass capillary tubes are made from borosilicate glass and are commonly used in laboratories and medical applications due to their high precision and accuracy. Glass capillary tubes are resistant to most chemicals and are easy to clean and sterilize, making them an ideal option for use in sterile environments.However, glass capillary tubes are fragile and can break easily, making them unsuitable for use in applications that require high pressure or flexibility. They are also relatively expensive compared to plastic and metal capillary tubes.ConclusionIn conclusion, selecting the correct capillary tube material is important to ensure that the tube can withstand the demands of the specific application. Stainless steel is the most commonly used material due to its high corrosion resistance and durability, while copper is ideal for use in refrigeration and air conditioning systems due to its excellent thermal conductivity. Plastic capillary tubes are lightweight and flexible, while glass capillary tubes are highly precise and suitable for sterile environments. By understanding the properties of each material, one can select the best option for their application.

Stainless Steel Corrugated Sheets for Durable and Versatile Construction Applications

In the world of metal pipe engineering, corrugated copper tubing is an underrated choice for many manufacturers. Though stainless steel and other metals are usually more popular options, copper has several unique qualities that make it a valuable commercial and residential building material. Additionally, with the added bonus of corrugation, it becomes strong and flexible enough to use in a range of applications.So, what exactly is corrugated copper tubing? Simply put, it's a type of pipe made from copper that has been shaped into a ridged, wave-like pattern. This pattern provides corrugated tubing numerous benefits over traditional smooth-walled pipes, such as improved bendability, durability, and resistance to pressure from external forces. Copper itself is also a beneficial material due to its inherent antimicrobial properties and its ability to resist corrosion.If you're looking to use metal pipes in your construction project, but are hesitant about using traditional materials, corrugated copper tubing may be worth considering. Its durability combined with its malleability makes it a great choice for various types of buildings. Additionally, using copper in general helps buildings become more energy-efficient, which can be a significant financial benefit over time.At HSH Metal Pipe, we manufacture a variety of stainless steel corrugated sheets to our customers' requirements. We also offer the ability to create corrugated copper tubing. Our pipes have been used in many successful applications like steel structure, construction, bridge engineering, plant and residential building, petroleum and gas conveying pipelines, and general machine manufacturing, such as mine driller, excavator, power trolley, truck, loader, scraper.Corrugated copper tubing is an excellent option for those looking for a sturdy, energy-efficient, and antimicrobial metal pipe. The process of creating a corrugated copper tube requires precision and care, two things we pride ourselves on at HSH Metal Pipe. It is a great choice when you want a material that can withstand high stresses and pressures while also being flexible, and that can be utilized in many different applications.In conclusion, Corrugated Copper Tubing is a great option if you're looking for a unique and versatile pipe material. It combines the antimicrobial properties and resistance to corrosion that copper is known for with the added strength and flexibility of a corrugated design. HSH Metal Pipe is a reliable option when needing high-quality and precisely made copper tubes for any of your construction or manufacturing needs.

Efficient Copper Tube Aluminum Fin Condenser for Improved Cooling

Condenser, Hydrophilic Aluminum, Galvanized End Plate, Smooth Copper Tube, Blue Fin Cover.When it comes to air conditioning systems, the condenser is one of the most critical components. It is responsible for removing heat from the compressed refrigerant and expelling it into the outdoor air. With that said, a high-quality condenser is essential for the efficient and reliable operation of your AC system. In this blog, we will discuss the copper tube blue fin condenser with cover and why it is a popular choice among HVAC contractors.The copper tube blue fin condenser with cover is a top-performing condenser that features a 9.52mm smooth copper tube. This tube is known for its excellent thermal conductivity properties, which means it can effectively transfer heat from the refrigerant to the surrounding air. Also, the hole space between the tubes is 25mm, and the row space is 21.65mm. These values represent the distance between the tubes, which allows for proper air circulation and heat dissipation.In addition to the copper tube, the condenser also features hydrophilic aluminum fins with a fin pitch of 2.7mm. Hydrophilic aluminum has a unique property that allows it to attract moisture and promote condensation. As a result, it can efficiently transfer heat from the refrigerant to the fins and onto the surrounding air. This process is essential for ensuring optimal cooling performance.Furthermore, the condenser comes with a 1mm thickness galvanized end plate that requires removing the brand name. The galvanized end plate is a durable and corrosion-resistant material that protects the condenser's internal components from external factors such as moisture and UV radiation. It also helps to keep the unit rigid and prevent damage from vibration and shock.One key advantage of the copper tube blue fin condenser with cover is the blue fin coating. The blue fin coating is a protective layer applied to the aluminum fins, which prevents corrosion and extends the lifespan of the condenser. This coating is a useful feature, especially in harsh environments where the condenser is constantly exposed to moisture and saltwater.In conclusion, the copper tube blue fin condenser with cover is an excellent choice for anyone looking for a reliable and efficient air conditioning condenser. With its smooth copper tubes, hydrophilic aluminum fins, and galvanized end plate, this unit can effectively transfer heat, resist corrosion, and withstand harsh operating conditions. Additionally, the blue fin coating adds an extra layer of protection and longevity to the condenser. So, if you are in the market for a new AC condenser, you should consider the copper tube blue fin condenser with cover.

Study Finds Large Deformation Heat During Rough and Medium Rolling of Rectangular Aluminum Square Tubes

The process research of rectangular aluminum square tube is an important topic for those who work with this type of material. In this blog post, we will explore the various stages of rolling and deformation that the aluminum undergoes, and how this affects the final product. Specifically, we will focus on the heat generated during the rough and medium rolling stages, and how it can impact the quality of the aluminum square tube.Rough and Medium RollingThe rectangular aluminum square tube is typically created through a process of rolling and deformation. During the rough rolling stage, the aluminum is passed through a series of rollers that apply significant pressure to the material. This pressure causes the aluminum to undergo large deformations, which leads to the generation of heat.The medium rolling stage follows the rough rolling stage, and involves further deformation of the aluminum using a series of smaller rollers. This stage also generates heat, although typically not as much as the rough rolling stage.Deformation HeatThe heat generated during the rough and medium rolling stages of the rectangular aluminum square tube can have a significant impact on the final product. If the heat is not managed properly, it can cause several issues including:1. Warping – When the rectangular aluminum square tube is exposed to high temperatures, it can warp and become misshapen.2. Uneven Metal Structure – The heat generated during the rolling process can cause the metal to have an uneven structure, which can lead to issues with strength and durability.3. Poor Surface Finish – If the heat generated during the rolling process is not controlled properly, it can result in a poor surface finish on the final product.Managing Heat GenerationTo ensure that the heat generated during the rough and medium rolling stages of the rectangular aluminum square tube is properly managed, several strategies can be employed. These include:1. Cooling – The aluminum can be cooled during the rolling process using water or other cooling methods. This can help to control the heat generated during the process and prevent warping and other issues.2. Rolling Speed – The speed at which the aluminum is rolled can be adjusted to control the amount of heat generated during the process. By rolling at a slower speed, less heat will be generated.3. Chemical Additives – Certain chemical additives can be added to the aluminum to help manage the heat generated during the rolling process. These additives can help to reduce warping, improve the surface finish, and create a more even metal structure.ConclusionThe process of creating rectangular aluminum square tube involves several stages of rolling and deformation, which generates a significant amount of heat. If this heat is not managed properly, it can lead to issues with the final product including warping, poor surface finish, and an uneven metal structure. To ensure that the heat generated during the process is controlled, strategies such as cooling, adjusting rolling speed, and using chemical additives can be employed. By properly managing the heat generated during the rolling process, a high-quality rectangular aluminum square tube can be produced that meets the needs of a wide range of industries and applications.Keyword: 50x50 Aluminium Square Tube

Effective Copper IUD for Women's Healthcare

Women's Healthcare Associates Introduces Copper IUD for Effective Birth ControlHouston, TX - Women's Healthcare Associates is proud to introduce the Copper IUD, a highly effective form of birth control that offers long-lasting protection against unintended pregnancy.At Women's Healthcare Associates, we understand the importance of providing women with personalized medical attention that takes into account their unique needs and preferences. That's why we are excited to offer the Copper IUD as an option for women who are looking for a reliable method of birth control.The Copper IUD is a small, flexible device that is inserted into the uterus by a healthcare professional. Unlike hormonal birth control methods, the Copper IUD contains no hormones and works by releasing copper to prevent fertilization. Once the device is in place, it can provide protection against unintended pregnancy for up to 10 years.One of the primary benefits of the Copper IUD is that it is highly effective at preventing pregnancy. In fact, it is more than 99% effective at preventing pregnancy, making it one of the most reliable forms of birth control available. Additionally, the Copper IUD is a non-hormonal method of birth control, which means it does not interfere with natural hormonal processes in the body.For many women, the Copper IUD is an attractive option because it is a long-lasting form of birth control that does not require daily attention. Once the device is in place, there is no need to remember to take a pill or use other forms of birth control.At Women's Healthcare Associates, we understand that choosing a method of birth control can be a personal and sometimes difficult decision. That's why we take the time to work with each patient to determine the best option for their individual needs.If you are interested in learning more about the Copper IUD or other forms of birth control, we encourage you to contact Women's Healthcare Associates today to schedule an appointment with one of our experienced healthcare providers. Our dedicated team of professionals is committed to providing personalized medical attention in a comfortable and welcoming environment, and we look forward to working with you to meet your healthcare needs.

Process Research Reveals Large Deformation Heat During Rough and Medium Rolling of Rectangular Aluminum Square Tube

Aluminum is one of the most widely used metals, with a plethora of applications in various industries. Among its various forms, rectangular aluminum square tubes are particularly useful in construction, transportation, and engineering applications due to their versatility, light-weight, and corrosion resistance properties. However, the manufacturing process of rectangular aluminum square tubes is complex and requires precise control to ensure the desired physical, chemical, and mechanical properties are achieved. Recently, Process Research of Rectangular Aluminum Square Tube has been conducted to improve the understanding of the manufacturing process. The research found that when the rectangular aluminum square tube is rough and medium rolled, large deformation heat will be generated. This heat needs to be removed efficiently to prevent damage to the material and ensure the desired properties are attained. The research was conducted by a team of experts at the renowned aluminum manufacturing company, {}. The researchers used advanced techniques such as computer simulations, experimental tests, and analytical models to study the behavior of aluminum during rolling. The team aimed to identify the key parameters that affect the manufacturing process of rectangular aluminum square tubes and propose solutions to optimize production and improve product quality. According to the lead researcher, the deformation heat generated during rolling is one of the most critical factors that affect the mechanical and physical properties of aluminum. When the material is subjected to large strain, it experiences a significant temperature rise, which can lead to problems such as cracking, warping, and surface defects. To address this issue, the team proposed several cooling strategies, including air cooling, water cooling, and oil cooling. The researchers also emphasized the importance of controlling the rolling speed, temperature, and reduction ratio to achieve the desired properties. They found that higher rolling speed and temperature tend to induce higher deformation heat, which in turn can affect the microstructure and mechanical behavior of aluminum. On the other hand, lower rolling speed and temperature can reduce deformation heat but may lead to lower productivity and higher manufacturing costs. Therefore, finding the optimal balance between these factors is crucial to maximizing the benefits of aluminum while minimizing the drawbacks. The research findings have significant implications for the aluminum manufacturing industry. By understanding the behavior of aluminum during rolling and developing effective cooling strategies, manufacturers can improve the quality and consistency of their products while reducing the risk of defects and damage. Moreover, the research can also lead to the development of new alloys and processing techniques that can further enhance the properties and applications of aluminum in various industries. In conclusion, Process Research of Rectangular Aluminum Square Tube is an essential step towards improving the understanding and optimization of the aluminum manufacturing process. The research conducted by the experts at {} has provided valuable insights into the behavior of aluminum during rolling and proposed practical solutions to address the challenges. With the growing demand for aluminum in various industries, it is crucial to continue investing in research and development to advance this versatile material and unlock its full potential.

Discover the Best Brass Plug Square Head Pipe Fittings for Your Plumbing Needs

Fittings, Brass Fittings, Brass Plug, Square Head.Brass Pipe Fittings: A Comprehensive GuideBrass is a timeless metal, popular for its durability, versatility, and appealing aesthetics. It's used in various applications, including plumbing and gas systems, thanks to its excellent resistance to corrosion, high pressure, and temperature changes. To achieve optimal performance, brass pipe fittings are crucial components in any pipe system, and the brass plug square head is one such fitting.What is a Brass Plug Square Head?A brass plug square head is a type of pipe fitting designed to close or seal off the end of a pipe or valve. Its square head design facilitates easy installation and removal with a wrench or pliers. The brass plug square head is available in different sizes, ranging from 8 mm to 28 mm, to suit different pipe sizes and diameters.Why Choose Brass Pipe Fittings?Brass pipe fittings offer numerous benefits compared to other materials. These include:1. Durability - Brass is a resilient metal that can withstand harsh environmental conditions, making it ideal for use in high-pressure and high-temperature applications.2. Corrosion Resistance - Brass is highly resistant to corrosion, rust, and tarnish, ensuring prolonged lifespan and optimal performance.3. Tight Sealing - Brass fittings are known for their tight sealing capabilities, minimizing the risk of leaks that can cause damage to the system.4. Aesthetics - Brass fittings enhance the overall aesthetics of a system, thanks to their elegant finish and lustre.Types of Brass Fittings PartsBrass fittings are available in a wide range of types and designs, depending on their intended use. Some of the common brass fittings parts include:1. Brass Elbows - These are used to connect pipes at an angle, usually 90 or 45 degrees.2. Brass Tees - These are used to connect three pipes of the same or different sizes.3. Brass Couplings - These are used to join two pipes of the same or different sizes.4. Brass Adapters - These are used to connect pipes with different thread types, diameters, or materials.5. Brass Caps - These are used to seal off the end of a pipe.Choosing the Right Brass FittingsChoosing the right brass fittings for your piping system is crucial to ensure optimal performance and longevity. It's essential to consider the following factors when selecting brass fittings:1. Material - Brass fittings can be made from different grades of brass with varying properties. It's crucial to choose the right one that meets the system's requirements.2. Size - Brass fittings come in different sizes to fit different pipe sizes. Choosing the right size ensures a tight fit and maximum efficiency.3. Thread Type - Brass fittings come in different thread types, including BSP, NPT, and Metric. It's essential to choose the right thread type to ensure a tight and secure connection.4. Operating Conditions - The operating conditions, such as pressure, temperature, and fluid type, should be considered when selecting brass fittings. It's essential to choose fittings that can withstand the system's operating conditions.Final ThoughtsBrass pipe fittings are vital components of any piping system. They offer numerous benefits compared to other materials, making them the preferred choice for plumbing and gas systems. The brass plug square head is one such fitting that ensures a tight seal and facilitates easy installation and removal. When choosing brass fittings, it's crucial to consider factors such as material, size, thread type, and operating conditions. By choosing the right brass fittings, you can ensure optimal performance and prolonged lifespan of your piping system.

How to Fix Leaking PVC Pipe Drain Fittings: Expert Tips

When it comes to plumbing, one of the most common problems homeowners face is leaks. Leaks can occur in various parts of the system, including pipes and fittings. While PVC pipes and fittings are generally reliable, they can still develop leaks. When this happens, it's crucial to fix the problem as soon as possible to prevent water damage and other costly repairs. In this blog, we'll show you how to repair seeping PVC pipe drain fittings, specifically from (brand name removed) products, and why you should consider switching to copper drain pipes to PVC.Step 1: Identify the Leaky FittingThe first step in repairing a seeping PVC pipe drain fitting is to identify the location of the leak. The most common signs of a leaky fitting include dampness, discoloration, and water stains on surrounding surfaces. Once you've identified the leak, turn off the water supply to the affected area.Step 2: Clean the AreaBefore you start repairing the leak, you'll need to clean the area thoroughly. Use a clean rag or paper towel to wipe away any water or debris around the fitting. Make sure the area is completely dry before proceeding.Step 3: Apply PVC CementNext, apply PVC cement to the joint between the pipe and fitting. Be sure to use the correct type of cement for your specific brand of PVC pipe. Apply a liberal amount of cement to the joint, taking care not to over-apply.Step 4: Press the Fitting in PlaceOnce the cement is applied, carefully press the fitting back into place. Hold it firmly in place for a few seconds to ensure a good seal.Step 5: Allow the Cement to DryFinally, allow the cement to dry completely. This can take anywhere from 30 minutes to several hours, depending on the specific brand of PVC and the conditions in your home. Once the cement is dry, you can turn the water supply back on and test the repaired joint for leaks.Why Switch to Copper Drain Pipe?While PVC pipe is a popular choice for drainage systems, it's worth considering the benefits of copper drain pipes. Copper pipes are more durable than PVC and are less likely to develop leaks over time. They're also resistant to corrosion and can withstand high temperatures, making them an ideal choice for hot water drains.Another advantage of copper pipes is their aesthetic appeal. Copper pipes have a classic, timeless look that can add value to your home. They're also valued for their environmental sustainability, as copper is a recyclable material.In terms of installation, copper pipes require specialized tools and expertise. However, the benefits of copper drain pipes make it a worthwhile investment for your home's plumbing system in the long run.In conclusion, seeping PVC pipe drain fittings can be easily repaired with PVC cement. However, it's worth considering the long-term benefits of switching to copper drain pipes. Copper pipes offer increased durability, resistance to corrosion, and aesthetic appeal, making them an excellent choice for homeowners looking for a reliable and sustainable drainage system.

Non-hormonal Birth Control Option: Copper Coil - Effective with Potential Side Effect

When it comes to family planning, modern contraception offers a range of options to choose from. From oral contraceptives to injections and patches, there's no shortage of hormonal options to prevent pregnancy. However, what happens when you want a non-hormonal choice? This is where the Copper Coil comes in.The Copper Coil is a small, T-shaped device made of plastic and wrapped in a wire coil. It is inserted into the uterus by a healthcare provider and works by preventing sperm from fertilizing an egg. For women who want to avoid hormones or cannot use hormonal birth control, the Copper Coil can be an excellent option.One of the primary benefits of the Copper Coil is its effectiveness. According to Planned Parenthood, the Copper Coil is 99% effective at preventing pregnancy. This means that out of every 100 women who use the Copper Coil, fewer than one will become pregnant within the first year of use.Another benefit is that the Copper Coil can be left in place for up to 10 years, making it one of the longest-acting forms of birth control. This makes it an excellent option for women who want a long-term contraceptive solution.However, there are also risks associated with the Copper Coil. One of the most common side effects is heavier or longer periods. The Copper Coil works by causing inflammation inside the uterus, which can lead to heavier menstrual bleeding. For some women, this may be a minor inconvenience, but for others, it can be a significant issue.In addition to heavy periods, some women may experience cramping, backache, or spotting during the first few weeks of having the Copper Coil inserted. These symptoms typically subside after a few weeks, but for some women, they may persist.There is also a risk of the Copper Coil becoming dislodged or falling out. This is more likely to happen during the first few months after insertion. Women should be aware of the signs of a dislodged Copper Coil, such as pain during sex or an unusual increase in discharge. If you experience any of these symptoms, you should contact your healthcare provider immediately.Another risk of the Copper Coil is that it does not protect against sexually transmitted infections (STIs). This means that if you are at risk of contracting an STI, you should still use a barrier method of contraception, such as condoms.In rare cases, the Copper Coil can lead to more serious side effects, such as ectopic pregnancy or uterine perforation. However, these complications are extremely rare and are more likely to occur in women who have not had children, have a history of pelvic inflammatory disease (PID), or have a history of uterine or cervical abnormalities.In conclusion, the Copper Coil can be an effective and long-lasting form of non-hormonal contraception. However, women should be aware of the potential side effects and risks associated with it. If you're considering the Copper Coil, it's essential to discuss your options with a healthcare provider and choose the best method of birth control for your individual needs.